Shop Clear Epoxy Resin Kits

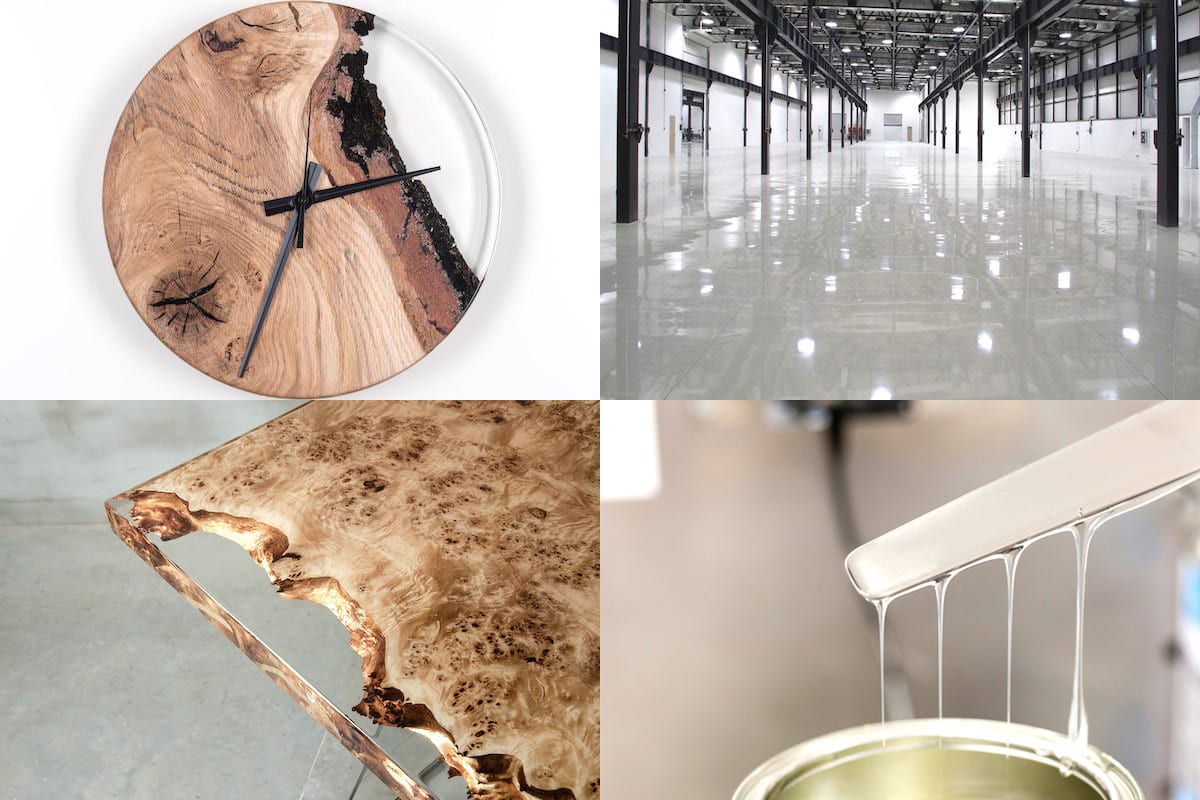

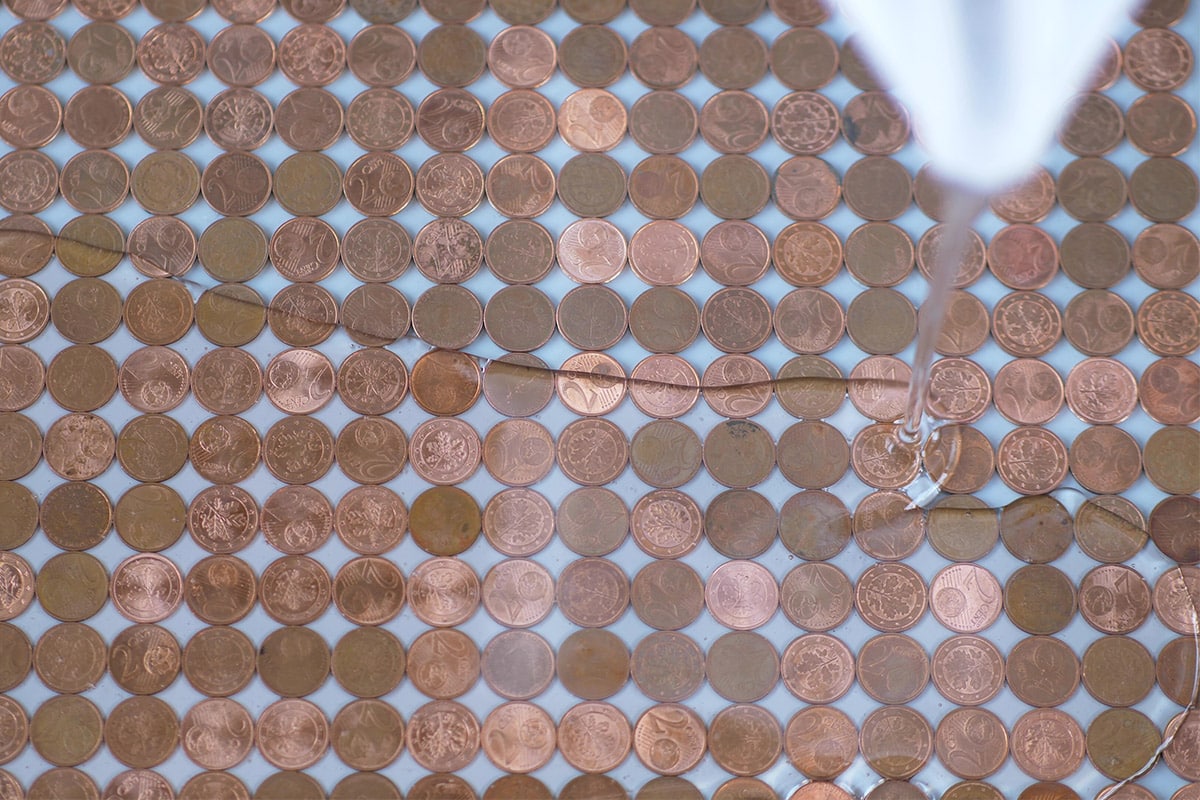

EPODEX clear epoxy kits are specially designed for your needs. Our 8 kits ensure that you will find the best epoxy for your project. Our designers created a large number of countertop and flooring kits. Be inspired by our unique and timeless designs. For glasses, coasters, and jewelry, purchase our handcrafted, artistic epoxy resin kit, available in clear or in combination with the largest selection of colors in the USA! If you want to make your own river table, our Deep Pour & Casting Epoxy Resin kit is the right choice for you.

-

$27.99$25.19

Pour up to 3/4″ | Perfect for jewelry, coasters, tumblers, small castings, woodworking and more | Clear

Pour up to 12″ | Perfect for river table, deep poured crafts, woodworking and more | Clear

Pour up to 1/16″ | Perfect for countertops, tabletops, bar tops and more | Clear

Pour up to 1/16″ | Perfect for design floors, garage floors, industrial floors and much more | Clear

Pour up to 1/16" - 3/8″ | Perfect for coating and sealing of all surfaces | Clear

Pour up to 1/16" - 2″ | Perfect for filling cracks in wood, concrete and other surfaces | Clear

Pour up to 1/16" - 3/8″ | Perfect for repairing floors, tiles, gas tanks, boats and more | Clear

Pour up to 1/16" - 3/8″ | Perfect for laminating and repairing boats, surfboards, and more | Clear